Get Your Free Quote…!

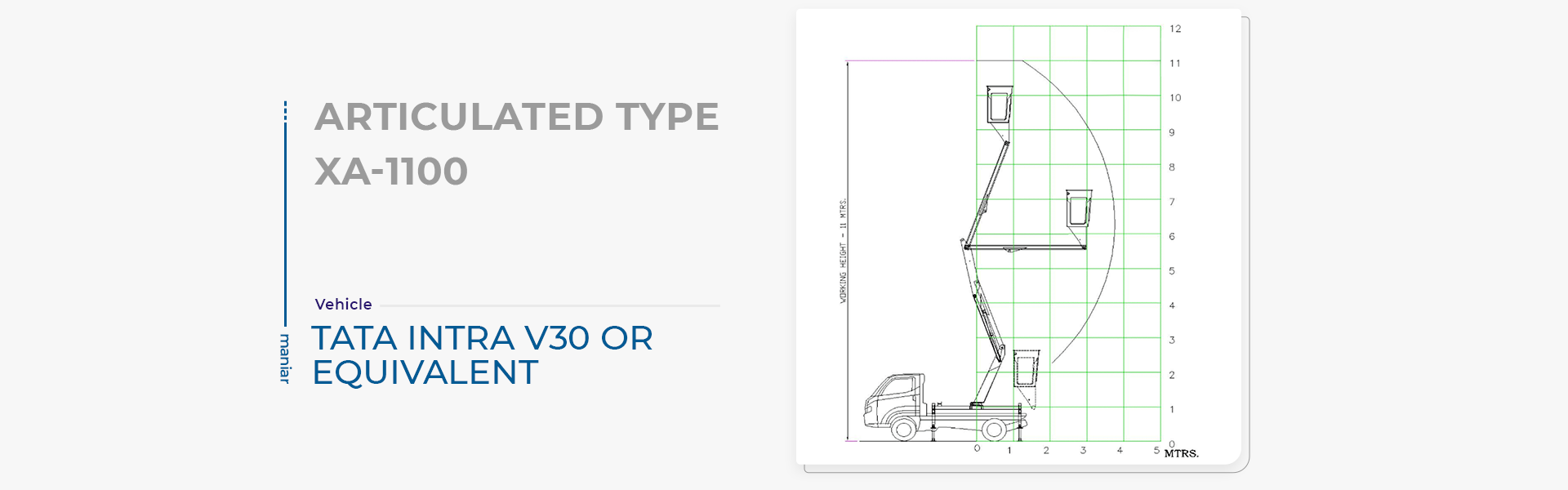

| Technical Specification | Aerial Work Platform Model Xa-1100 | |

|---|---|---|

| VEHICLE | TATA INTRA V30 OR EQUIVALENT | |

| TYPE | ARTICULATED TYPE | |

| Performance | Working Height | 11m |

| Cage Floor Height | 9m | |

| working Outreach | 3.8m | |

| Slewing | 360 cont. | |

| Safe Load | 200kg | |

| Features | Design | Side boom design helps the operator to operate any boom at any angle. Hence no boom operating sequence required. |

| Direct cage entry from chassis deck. | ||

| Designed as per EN 280 safety standard norms | ||

| There should not be any boom or structure over driver’s cabin | ||

| Maximum overall height in collapse condition- 2900mm | ||

| Boom | Type | Articulated side boom type |

| Material | High tensile steel min yst 700N/mm2 | |

| Section | Octagonal boom section | |

| Pivot Points | Self lubricating | |

| Boom Profiles | Plasma/laser cut | |

| Hydraulic Ram | Type | Double acting |

| Tube | Horned tube | |

| Rod | hardened chrome plated | |

| Seals | Reputed make | |

| Stabilizers | Type | Hydraulic operated |

| Numbers | 4 | |

| Over travel | To level the vehicle on uneven ground | |

| Lock Valves | Fitted to all stabilizers for safety | |

| Stabilizer Control | Independent control | |

| Hydraulic pump | Make | Dowty/equivalent make |

| Type | Gear pump | |

| Drive | From vehicle's engine thru PTO. | |

| Slewing | Type | Worm reduction slew bearing |

| Slewing Range | 360 degree continuous | |

| Cage leveling | Type | Mechanical leveling-parallel linkage type |

| Operator Cage | Type | FRP 700X850X900mm |

| The basket have non slip flooring | ||

| Drain holes for water drainage | ||

| Tool box inside the basket. | ||

| Working light | ||

| Emergency switch | ||

| Safety hooks inside the basket. | ||

| Controls | Make | Walvoil/equivalent control valve |

| Stabilizer Controls | Independent control at chassis deck | |

| Base Control |

Switch control panel at base. Lever cum solenoid control valve is fitted at base |

|

| PLC Control |

Safety system has been integrated with controls by use of program in a programmable

logical controller of European brand for high reliability and long service

life. EN/IEC 61000 standard CE mark |

|

| Safety | Emergency Pump |

Emergency hand pump is provided to enable stopping of the equipment in case of

pump/engine failure. |

| Emergency switch | Emergency switch is provided to hold the cage in fix position after reaching top in progress. This switch helps to stop lowering cage in any unforeseen situation while working. | |

| Emergency cut off at base control | ||

| Emergency cut off at basket control | ||

| Boom-stabilizer interlocks | Boom operates only after stabilizers are extended. | |

| Stabilizers lock when machine is open. | ||

| Safety belt anchorage points on platform. | ||

| Pilot check valves on hydraulic stabilizers. | ||

| Over center valve on boom cylinders. | ||

| Slew restriction when boom is in its cradle support. | ||

| Max pressure valve on hydraulic circuit. | ||

| Device to signal outriggers not in resting position. | ||

| Flow restrictor valve on hydraulic circuit. | ||

| Spirit level indicator | ||

| PLC based electronic circuit for safety interlocking. | ||

| Spot light in the basket. | ||

| IP protected control box | ||

| Paint | Primer | Two coat of epoxy primer |

| Finish | Two coat of PU/synthetic enamel. | |