|

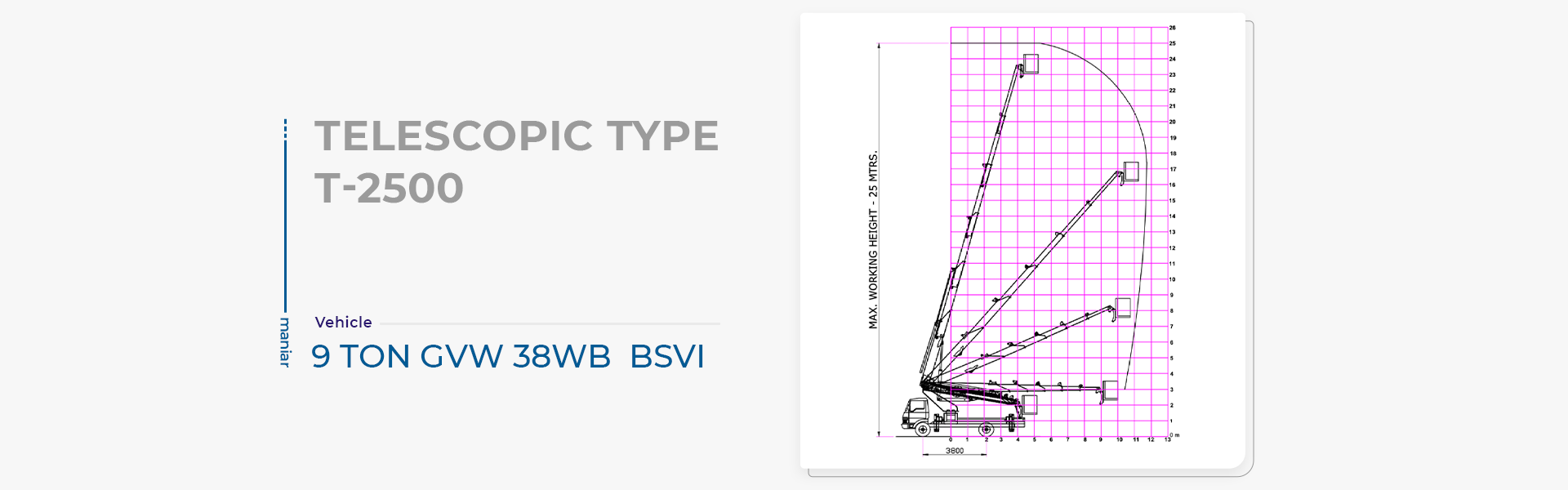

Vehicle

|

9 TON GVW 38WB BSVI

|

|

Performance

|

Working Height

|

25m

|

|

|

Cage Floor Height

|

23m

|

|

|

Outreach

|

10m

|

|

|

Slewing

|

360 cont.

|

|

|

Safe Load

|

200kg

|

|

Boom

|

Type

|

Telescopic type

|

| |

Material

|

High tensile steel min yst 700n/mm2

|

| |

Section

|

Box section

|

| |

Pivot points

|

Self-lubricating

|

| |

Boom profiles

|

Plasma/laser cut

|

|

Hydraulic Ram

|

Type

|

Double acting

|

|

|

Tube

|

Horned tube

|

|

|

Rod

|

Induction hardened chrome plated

|

|

|

Seals

|

Reputed make

|

|

Stabilizers

|

Type

|

Hydraulic operated H type hydraulic extendable and vertical

|

|

|

Numbers

|

4

|

|

|

Over travel

|

To level the vehicle on uneven ground

|

|

|

Lock Valves

|

Fitted to all stabilizers for safety

|

|

|

Stabilizer Control

|

Independent control

|

|

Slewing

|

Type

|

Worm reduction slew bearing

|

|

|

Slewing Range

|

360 degree continuous

|

|

Cage leveling

|

Type

|

Mechanical and hydraulic leveling

|

|

Operator Cage

|

Type

|

Aluminium 1200x1100x800mm

|

|

|

|

The basket have non slip flooring

|

|

|

|

Drain holes for water drainage

|

|

|

|

Tool box inside the basket.

|

|

|

|

Working light

|

|

|

|

Emergency switch

|

|

|

|

Safety hooks inside the basket.

|

|

Controls

|

Stabilizer Controls

|

Independent control at chassis deck

|

|

|

Base Control

|

Switch control panel at base

|

|

|

Cage Control

|

Wireless remote control

|

|

|

Type

|

Hydraulic leveling

|

|

|

PLC Control

|

Safety system has been integrated with controls by use of program in a programmable

logical controller of European brand for high reliability and long service life.

|

|

Safety

|

Emergency Pump

|

Emergency hand pump is provided to enable stopping of the equipment in case of

pump/engine failure.

|

|

|

Emergency switch

|

Emergency cut off at base control

|

|

|

|

Emergency cut off at basket control

|

|

|

Boom-stabilizer interlocks

|

Boom operates only after stabilizers are extended.

|

|

|

|

Stabilizers lock when machine is open.

|

|

|

|

Safety belt anchorage points on platform.

|

|

|

|

Pilot check valves on hydraulic stabilizers.

|

|

|

|

Over center valve on boom cylinders.

|

|

|

|

Slew restriction when boom is in its cradle support.

|

|

|

|

Max pressure valve on hydraulic circuit.

|

|

|

|

Device to signal outriggers not in resting position.

|

|

|

|

Flow restrictor valve on hydraulic circuit.

|

|

|

|

Spirit level indicator

|

|

|

|

PLC based electronic circuit for safety interlocking.

|

|

|

|

Spot light in the basket.

|

|

Paint

|

Primer

|

Two coat of epoxy primer

|

|

|

Finish

|

Two coat of PU/synthetic enamel.

|

|

Optional

|

Cage Rotation

|

Hydraulic rotation

|

|

|

|

45+45 degree both side

|

|

|

Vehicle Auto leveling

|

Automatic leveling and stabilization system increase the comfort and ease of use

with single push button. The system is fully automatic which allows the leveling

process to be completed within very short time.

|

|

|

Digital Safe Load Indicator

|

Safe load indicator is safety control unit mounted in cage to alert the operator if

the cage is exceeding the safe operating load of the machinery. If the load exceeds

the rated limit, it prevents the some boom function.

|